Welcome to Precibalance Dynamic Balancing Machines. Makers of balancing machine and balancing machine instrumentation. Precibalance offers economic, reliable and precise dynamic balancing machines for wide variety of applications with weight capacities from few hundred grams to many thousand kilo grams. Well balanced parts improve the service life and lower the vibration levels of machinery. The high performance of the Precibalance balancing machines enables you to balance your parts to the desired levels accurately, reliably and efficiently. G2.5 and G1 grade balancing machines are available as standard offering. Better grades offered on request.

Table of Contents

Balancing machines

A Balancing machine is a machine used for the balancing of rotating components. Balancing of rotors enable the rotors to run smoothly, with lower vibration levels and enable improved speed, productivity and efficiency of the machines they run on.

New to Balancing? Read about the Basics of Balancing & Balancing Machines

Precibalance has got proven expertise over three decades in supplying dynamic balancing machines in many applications working in more than eighty three countries across the world in various applications such as automotive components, aerospace applications, machine tools and many other applications across various industries.

Balancing Machines are available in a wide range of capacities for handling wide varieties of components such as turbines, electrical rotors, turbochargers, pulleys, spindles, fans, textile components, rolls, and many others.

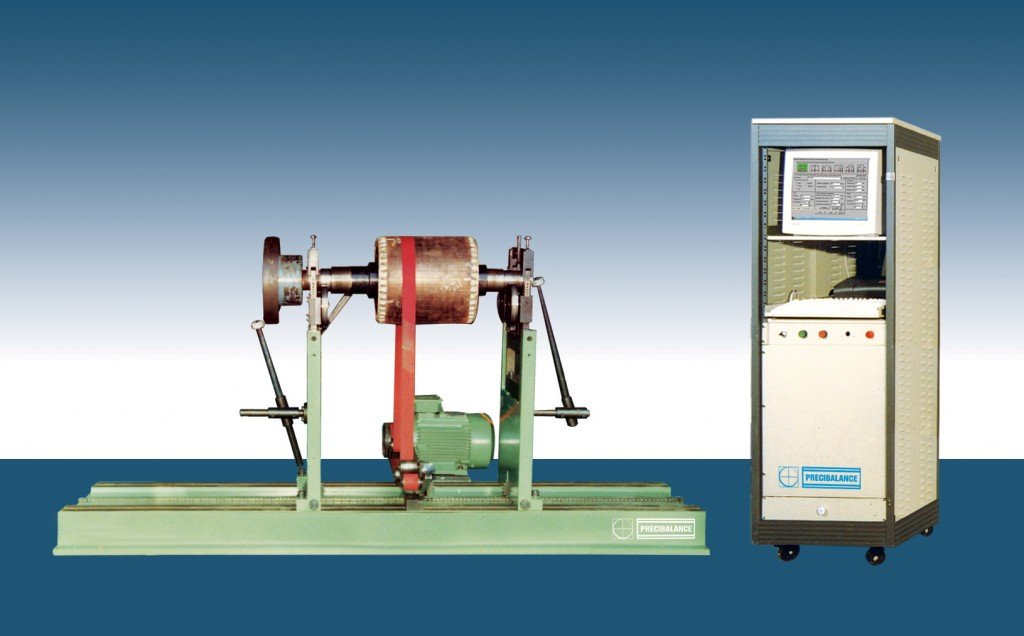

Horizontal Balancing Machine

Horizontal balancing machines are balancing machines where the rotor is mounted horizontally rested on two supports. A horizontal balancing machine is well suited for longer rotors where the rotor is supported between two or more bearing journal areas.

A horizontal balancing machine generally consists of a bed, two pedestals that rest on the bed, rollers fitted on the pedestals to allow the rotor to rotate freely, a drive arrangement to rotate the rotor to the desired speed. The rotor is mounted on the rollers supports and driven by a drive arrangement.

Horizontal balancing machines comes in options of either end drive, belt drive or a combination drive option having both an end drive and a belt drive. So, Horizontal Balancing Machines are well suited for components such as electrical rotors, rolls, turbines, turbochargers, fans, textile components , paper industry components and many others.

Precibalance horizontal balancing machines are available for components weighing from few hundred grams to many thousand kilograms.

Belt Drive Balancing Machine

Belt drive balancing machines are balancing machines where the drive arrangement uses a belt. The rotor is mounted on the machine between the supports and driven up-to balancing speed using a belt drive arrangement and belts. The use of the belts instead of transmission components eliminate the error induced by the drive transmission and associated tooling. Belt drive balancing machines are suitable for components that require precise balancing and can be driven with belts.

Belt drive machines are well suited for applications such as electrical rotors balancing, rolls, turbines where high precision is required and the rotor has a surface available for driving with a belt.

End Drive Balancing Machine

End drive balancing machines are balancing machines where the drive arrangement uses a head stock and a universal shaft to spin the rotor at the balancing sped. The rotor is mounted on the machine between the supports and driven up-to balancing speed using an end drive arrangement and an universal shaft coupling.

End drive balancing machines are typically used where the rotor needs high torque and positive drive. They are also used in applications where belt slippage may occur or there is no provision to mount a belt.

End drive balancing machines are well suited for applications such as fan balancing,oil mill component balancing

Combination Drive Balancing Machine

A combination drive balancing machine is a combination of both an end drive and a belt drive mounted on a common bed and pedestal assembly.

A combination drive balancing machine combines the advantages of both an end drive balancing machine and a belt drive balancing machine giving a versatile machine able to handle a wide range of components.

Vertical Balancing Machine

Vertical balancing machines have the rotor to be balanced mounted vertically on them. Vertical balancing machines are suited for rotors where the design of the component calls for balancing on a vertical balancing machine. The vertical balancing machine is suited for production applications since the tool can remain fixed on the machine and the component can be swapped and measured quickly.

Assembly Balancing Machine

Assembly balancing machine balances a whole rotor assembly in it’s own bearings. An assembly balancing machine enables balancing of rotor assemblies to fine levels. This is because balancing in an assembly eliminates the errors from the assembly tolerances of the sub assemblies.

Assembly balancing machines are well suited for rotors running under their own power. Often, the assemblies are also balanced at their service speeds to ensure fine balancing levels at service speed operation.

For some applications such as fans Precibalance Assembly Balancing Machines also come with a reference-less design where in a reference sticker is not required during the balancing process. This saves on time and fatigue on fixing the reference in a production application. Visit the assembly balancing page for more information.

Precibalance assembly balancing machines are designed in a modular fashion making the balancing machine versatile even for assembly balancing operation. By changing the tooling, assemblies being balanced can be changed enabling the machine to be used for a variety of component assemblies.

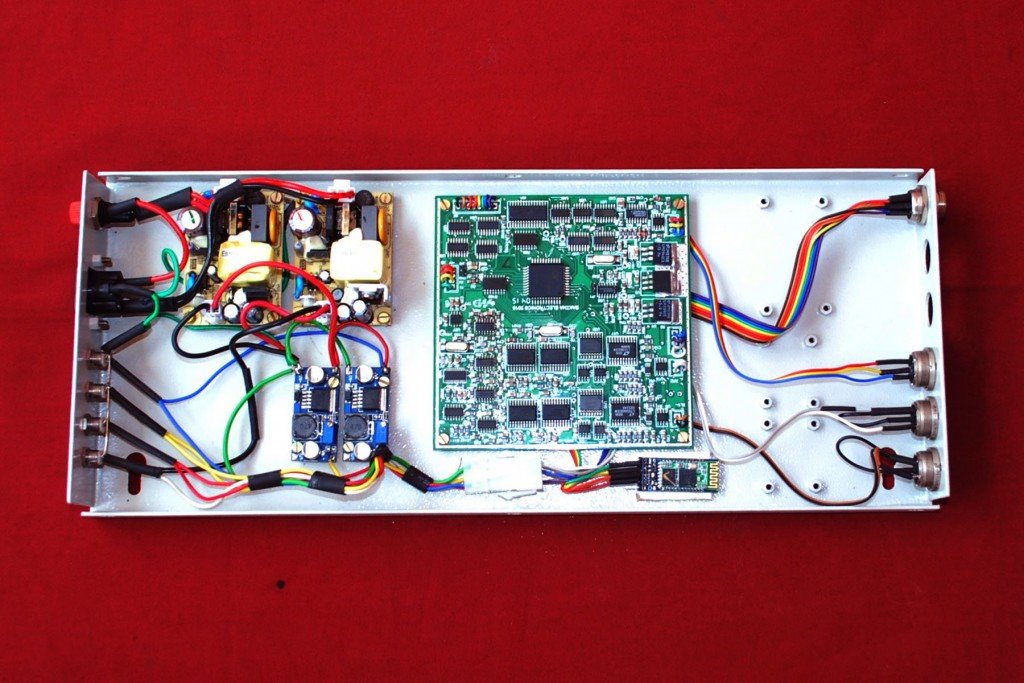

Balancing Instrumentation

A balancing instrumentation consists of vibration sensors, RPM sensors, rotary encoders and the signal processing electronics and software to convert the raw sensor data to a readable unbalance result. The balancing machine instrumentation also extracts the unbalance signal from a multitude of noise sources such as other rotating elements of the machine, electrical noises in an industrial environment etc. The excellent unbalance signal extraction capability of Precibalance balancing instrumentation ensures accurate unbalance measurement and ease of correction on Precibalance dynamic balancing machines. Precibalance balancing instrumentation is designed to make the process of balancing simple, quick and effective.

A Precibalance Balancing Instrumentation kit normally comes with the following

- Precibalance Balancing Electronics

- Force / Acceleration sensors. Specify while ordering if you would like to upgrade a hard bearing balancing machine or a soft bearing balancing machine. Normally, we supply force sensors for hard bearing balancing machines and ICP compatible accelerometers for soft bearing balancing machines.

- RPM sensor.

- Rotary encoder

- Balancing software

- Power supply and inter connecting cables

The balancing machine upgrade kit is compatible with PC running Windows 7,8 or 10. A USB port is required for communication with the electronics.

The Precibalance balancing instrumentation is designed with flexibility and ease of use. The modular design of the hardware and software enable the Precibalance balancing instrumentation to be fitted on other make balancing machines quickly with little effort.

- Retrofit and upgrade your old balancing machine with a modern unbalance measurement balancing instrumentation.

- Revive electrically and mechanically functional balancing machines with faulty electronics by replacing the old electronics with a Precibalance balancing electronics.

- Works with almost any make of balancing machines: hard bearing balancing machine, soft bearing balancing machine, vertical balancing machine, horizontal balancing machine at most load capacities and speeds.

- Works with different types of sensors such as piezo electric force sensors, ICP accelerometers.

- The balancing instrumentation along with the site balancing software can also be used as a on-site balancing system.

- Measurement time as low as 2 seconds optionally available for special applications.

- Also use as turn-key measurement system for special purpose or custom balancer.

- Automatic calibration function – Quick and easy to set-up and use. The automatic calibration ensures your upgraded machine is calibrated quickly and precisely.

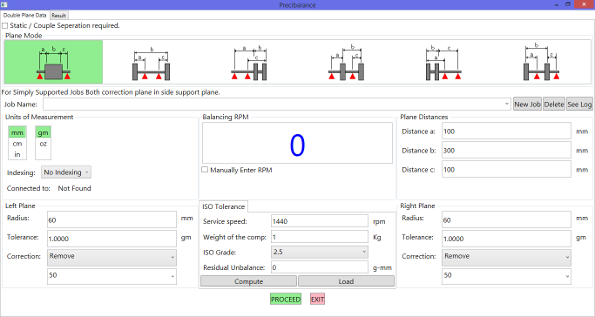

Balancing Software

Balancing software is the interface between the balancing machine user and the balancing machine electronics. The balancing software processes the signals from the sensors and balancing instrumentation, performs computation, displays results to the operator and handles the control of the balancing instruments. With the modern PC processing power, balancing software has become powerful automating most of the computation that were traditionally done manually. The improved processing power also enables use of algorithms that deliver results with better accuracy and better balancing machine performance.

Precibalance Balancing Software is designed for use with Precibalance Balancing Instrumentation. The Precibalance Balancing Software has a host of features standard that enables the user to balance their rotors quickly and efficiently.

- Software for use with Single Plane Balancing Machine or Two Plane Balancing Machine

- Software for Hard bearing balancing machine or Soft bearing balancing machine

- Intuitive to use

- Polar graphics display

- Large font result display for clear unbalance indication.

- Built in place weights function for split rotor balancing like segmented rotors, wherein some angles have no material available for correction

- Mutliple language support.

- Printing and logging function to have print and saving to disk of the balancing reports.

Precibalance balancing software runs on Windows 7,8 or 10 and requires one free USB port for connection with the balancing machine electronics.

Site Balancer

The site balancer is a device that is used to perform balancing on rotating parts on site or in-situ conditions. Unlike, balancing on traditional balancing machines, a site balancer utilizes vibration sensors such as accelerometers placed on the machine that contains the rotor that needs to be balanced. The balancing process is done without removing the rotor from the machine it is operating on.

Precibalance Site Balancer brings the excellent signal processing of the Precibalance Balancing Instrumentation to on-site balancing. The high noise rejection capabilities of Precibalance Balancing electronics delivers fine levels of site balancing in an industrial environment where there may be many sources of mechanical and electrical noise.

The Precibalance Site Balancer comes standard with the following

- Precibalance electronics with two plane balancing

- ICP compatible Accelerometers

- RPM sensor laser type

- Software for site balancing in one and two plane.

This kit along with a laptop completes a portable balancing instrument kit. As with the Precibalance Balancing Machine software, the software for Precibalance Site Balancer also comes with Printing and Logging of balancing reports as a standard feature.

Site balancing can be done for various applications such as

- Fan balancing

- Blower balancing

- Pump balancing

- Turbine balancing

- CNC Machine spindle balancing

- Grinding wheel balancing on a grinding machine

- Air handling equipment

and many more applications.

Site Balancing Services

Precibalance also offers site balancing services. Contact us for more information.